En collaboration avec GERTEC, Swalmec dispose de différentes pompes à la location.

Actuellement nous avons à disposition les pompes reprises ci-dessous. Pour connaître leurs caractéristiques, cliquez sur le nom sous la photo.

Découvrez ci-après les spécifications techniques, si vous souhaitez plus d’informations ainsi que les tarifs, n’hésitez pas à prendre contact avec nous au +32 (0) 67 55 21 13 ou info@swalmec.be.

Gertec SP-550-2

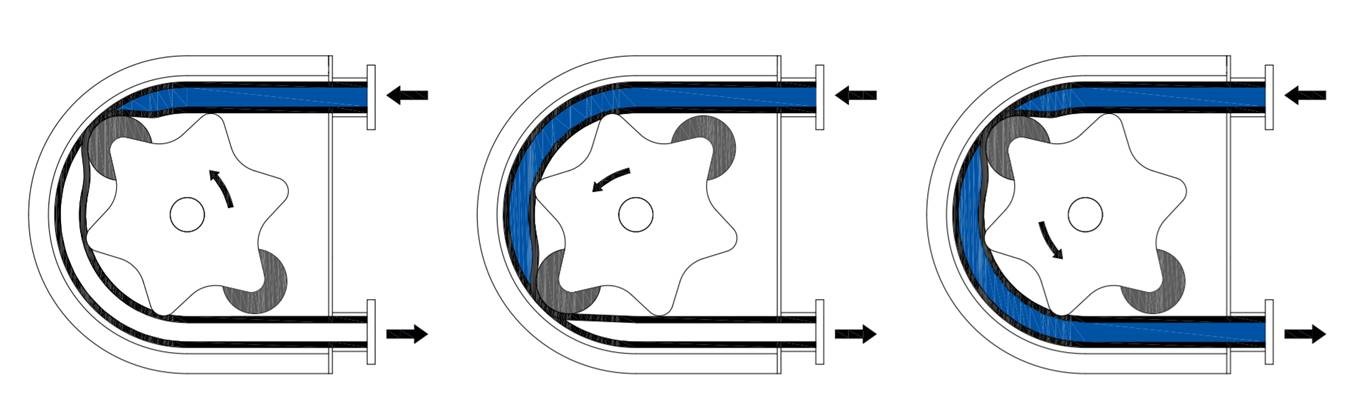

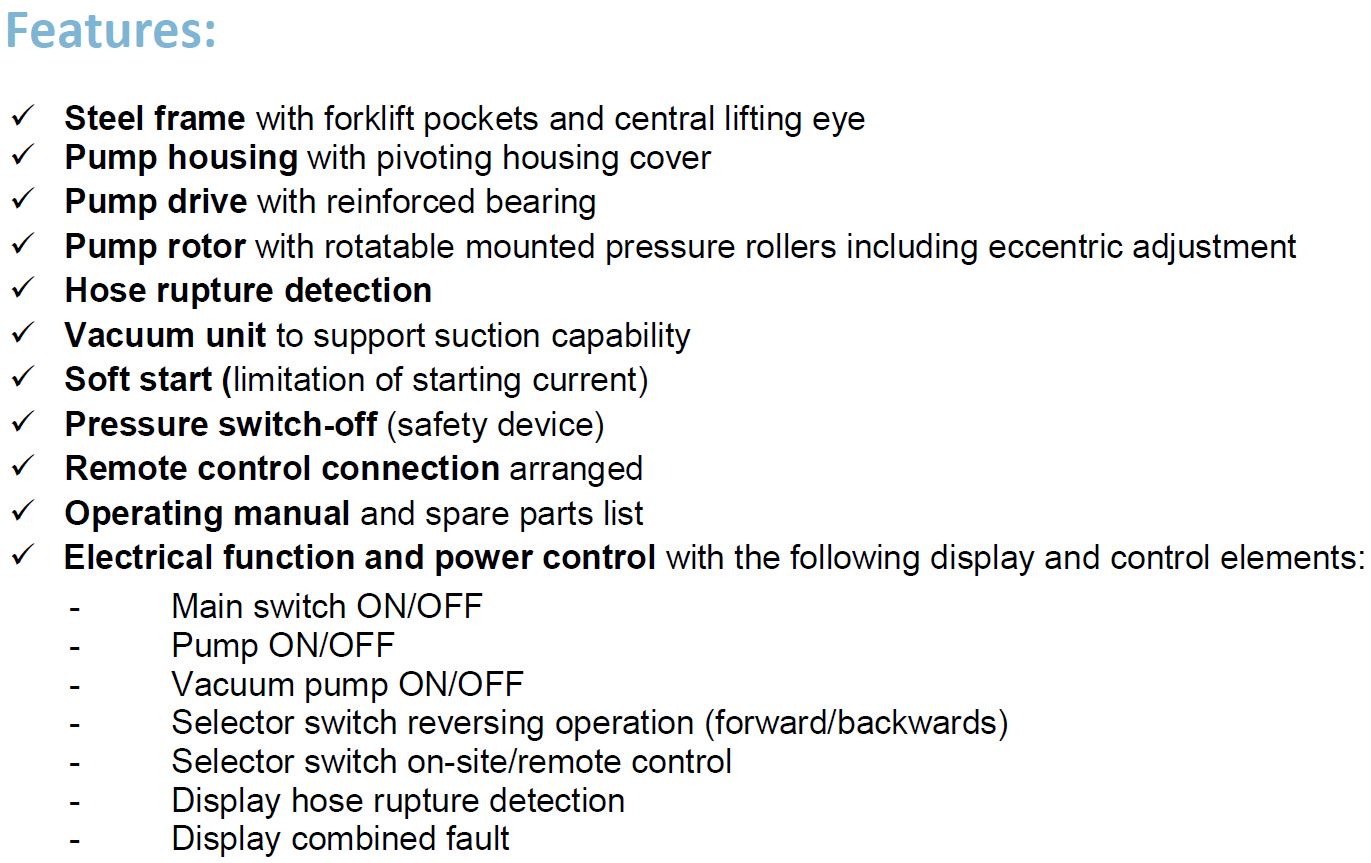

The GERTEC hose pump SP-550-2 (2 speeds) is appropriate for pumping fluids containing a high proportion of solids and abrasives. The electrical engine of the automatic priming pump is reversible (forward/ backward) and has 2 speeds for pumping. The handling of the compact self-priming pump is very easy.

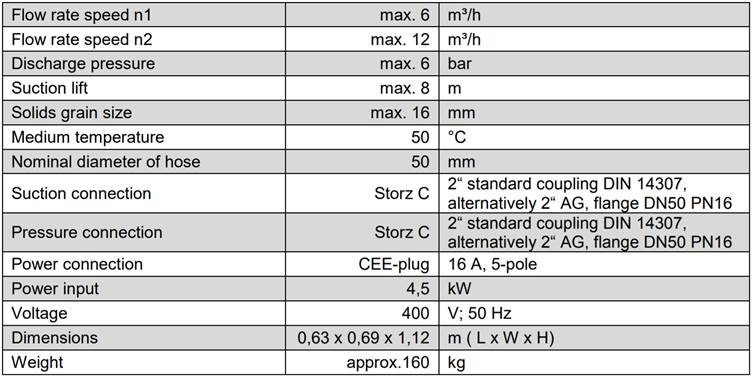

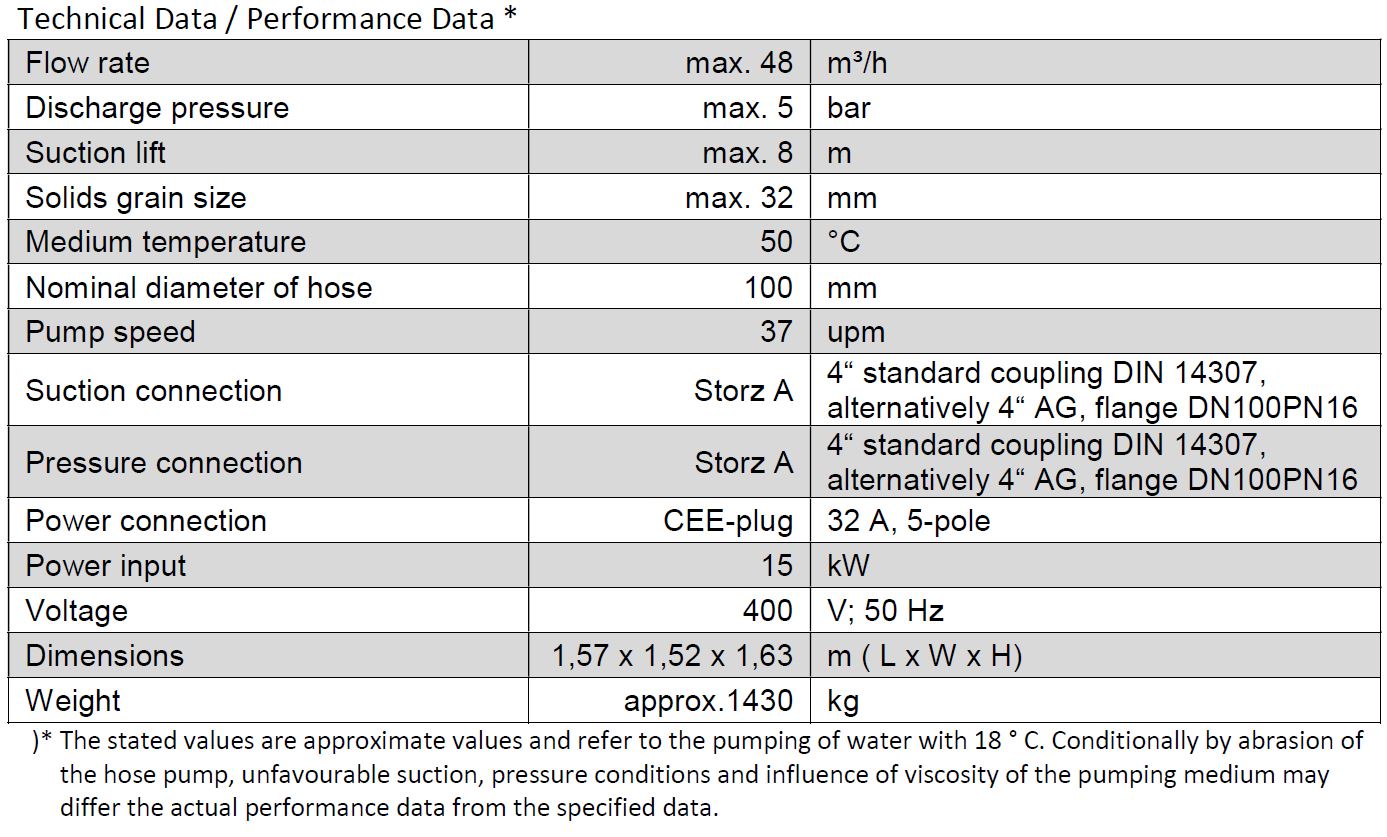

Technical Data:

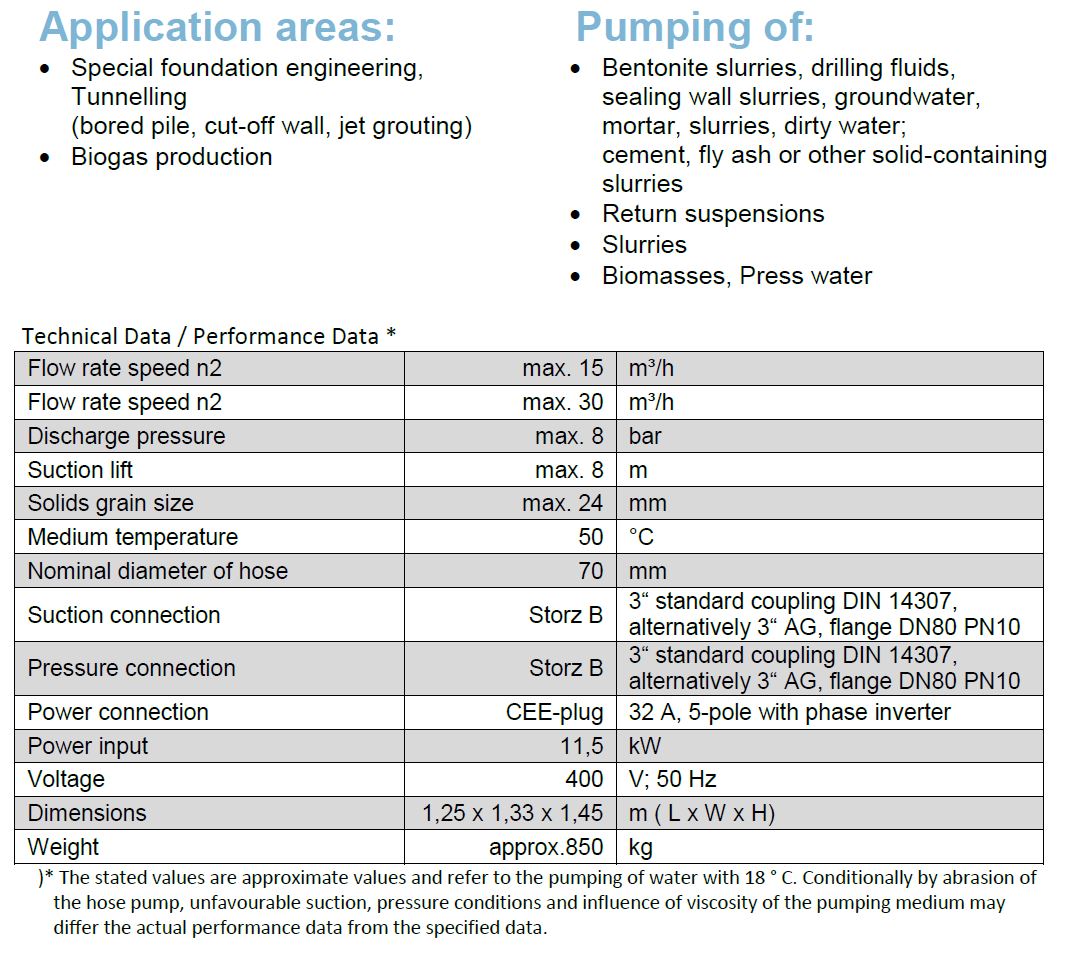

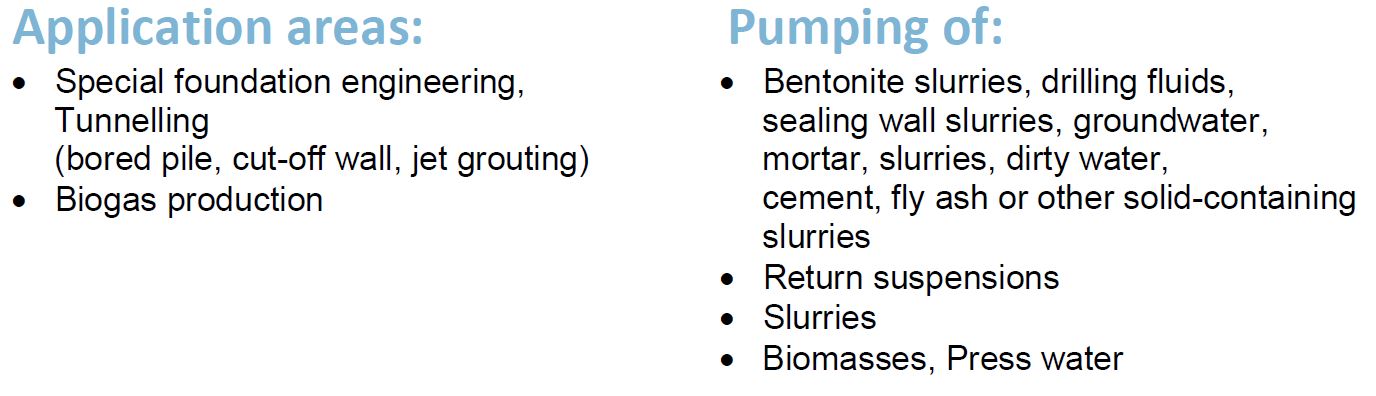

Applications:

- Special foundation engineering (bored pile, cut-off wall, jet grouting)

- Tunneling

- Biogas production

Possible pumping media:

- drilling fluids

- slurries, abrasive, corrosive

- wastewater

- cement slurry

- bentonite slurry

- foamed concrete

- mortar

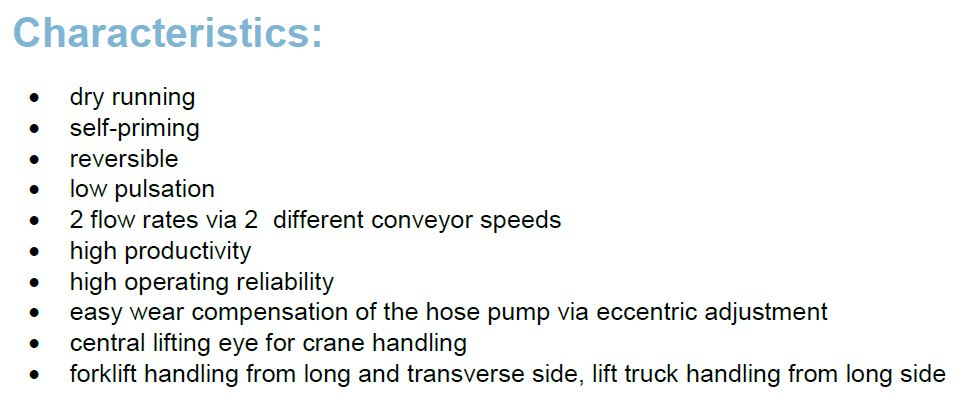

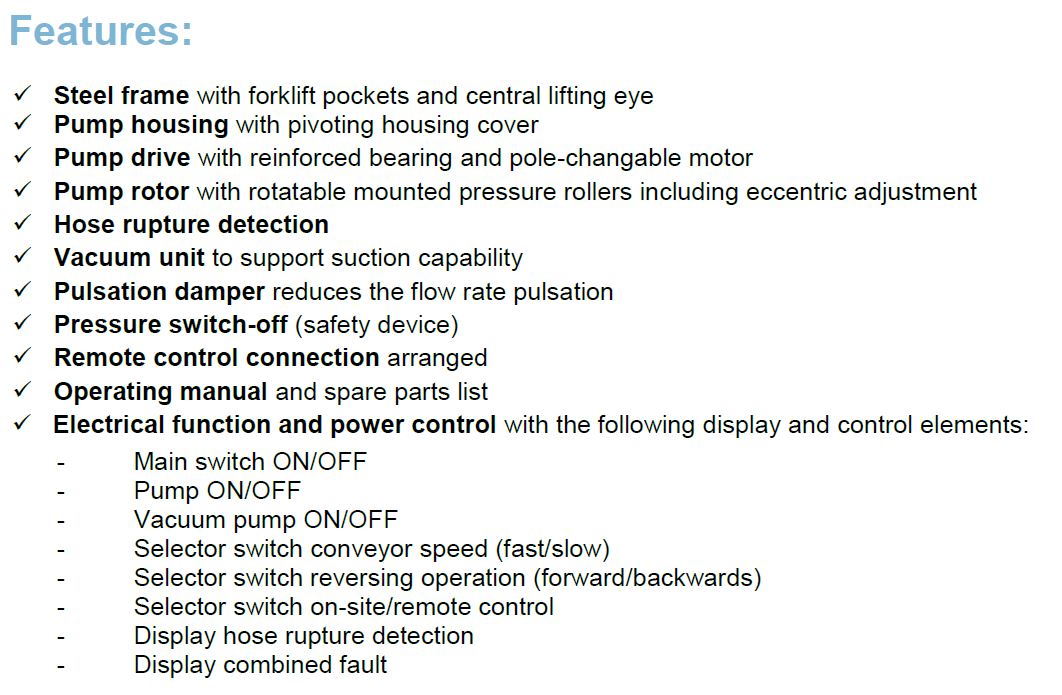

Main features and advantages:

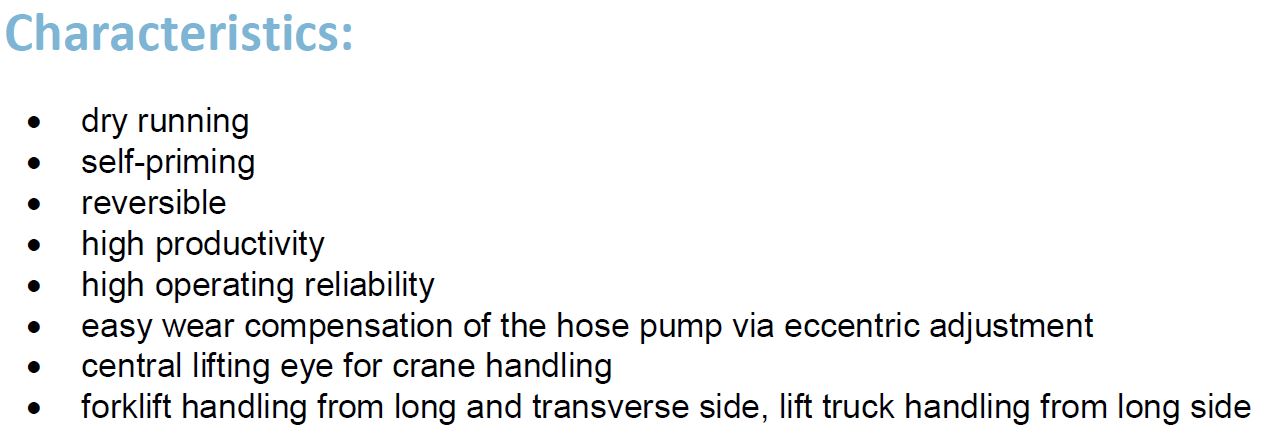

- safe to run dry

- self-priming

- reversible

- high performance

- high reliability

- easy operation

- easy transport handling

Gertec IS-38-E

Pour plus d’information, cliquez ici

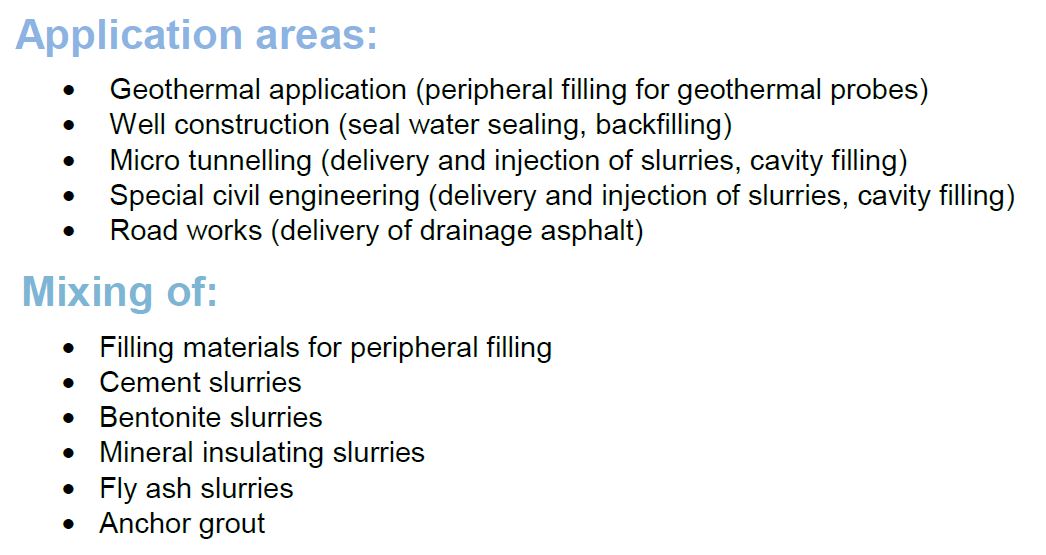

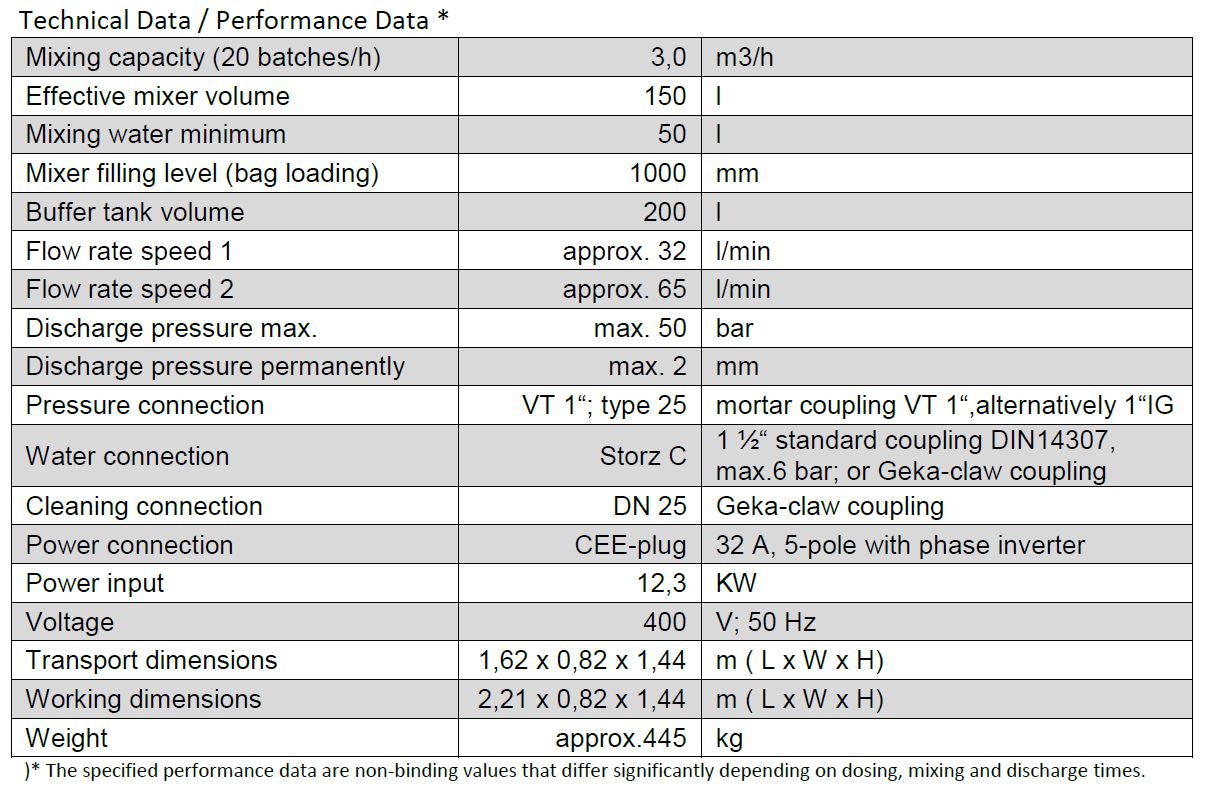

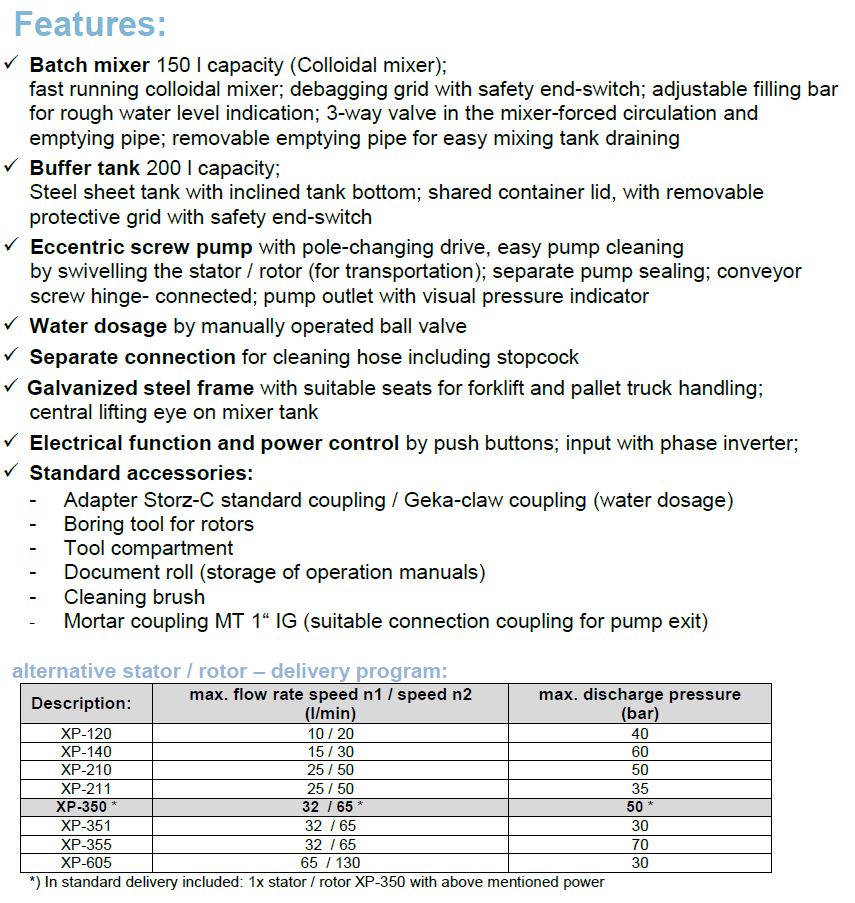

Gertec IS-100-EA

Pour en savoir plus, cliquez ici

Gertec IS-150-EA

Plus d’information, cliquez ici

Français

Français  Nederlands

Nederlands  English

English